LT3756EUD-2#PBF and LT3756EUD-2#TRPBF—two parts from Linear Technology (now Analog Devices). Both at first glance appear almost identical.

However, there’s a subtle but important distinction between the two after closer examination. While both are functionally the same, their packaging is the key difference.

In this blog post, we will know not only the difference of them in packaging. But also the features, description, and applications, with a special focus on the two variations mentioned.

Key Differences Between LT3756EUD-2#PBF and LT3756EUD-2#TRPBF

At the core of these two part numbers is the same LT3756 controller. Without difference in the functionality or electrical characteristics between the two. The sole distinction lies in the packaging:

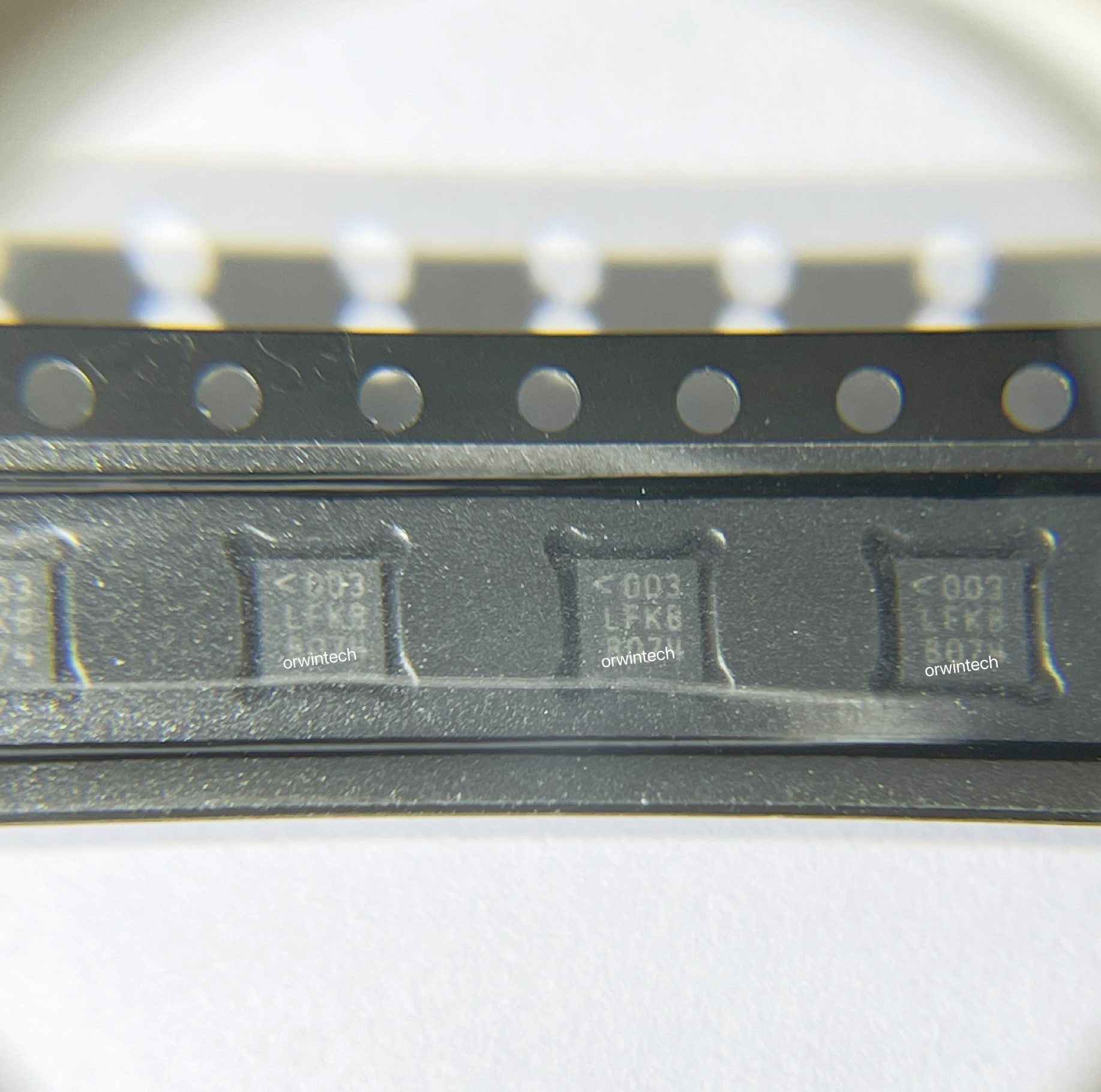

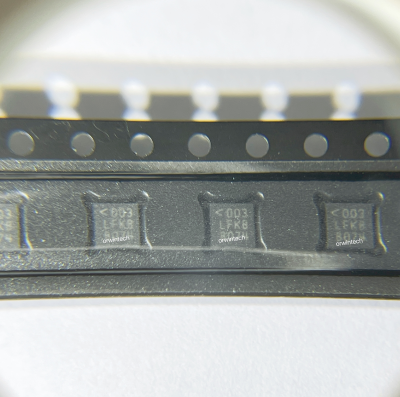

· LT3756EUD-2#PBF: This part is packed in tubes. Use tube packaging in components , manually place into a machine , or use in low-volume production.

· LT3756EUD-2#TRPBF: This part is packed in tape and reel . Tape and reel packaging design for automated assembly processes. Suitable for mass production where components fed into automate pick-and-place machines.

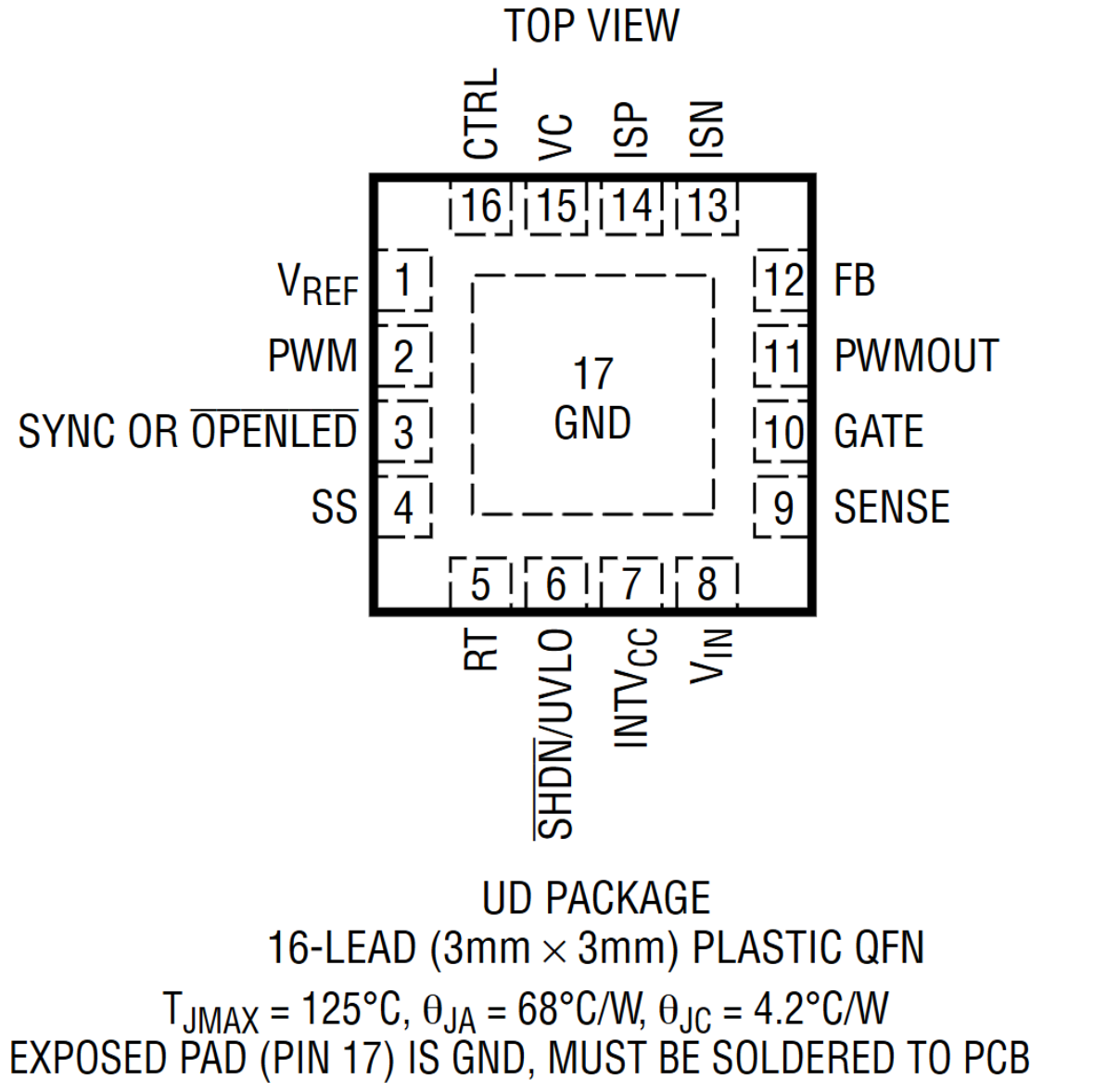

Pin Configuration

Understanding the LT3756EUD-2#PBF and LT3756EUD-2#TRPBF

LT3756EUD-2 DC/DC controllers designed to operate as a constant-current source for driving high current LEDs.

They drive a low side external N-channel power MOSFET from an internal regulated 7.15V supply.

The fixed frequency, current-mode architecture results in stable operation over a wide range of supply and output voltages.

A ground referenced voltage FB pin serves as the input for several LED protection features. And also makes it possible for the converter to operate as a constant-voltage source.

To optimize efficiency, performance or external component size. A frequency adjust pin can program the frequency from 100kHz to 1MHz.

They sense output current at the high side of the LED string. High side current sensing is the most flexible scheme for driving LEDs, allowing boost, buck mode or buck-boost mode configuration. The PWM input provides LED dimming ratios of up to 3000:1. And the CTRL input provides additional analog dimming capability.

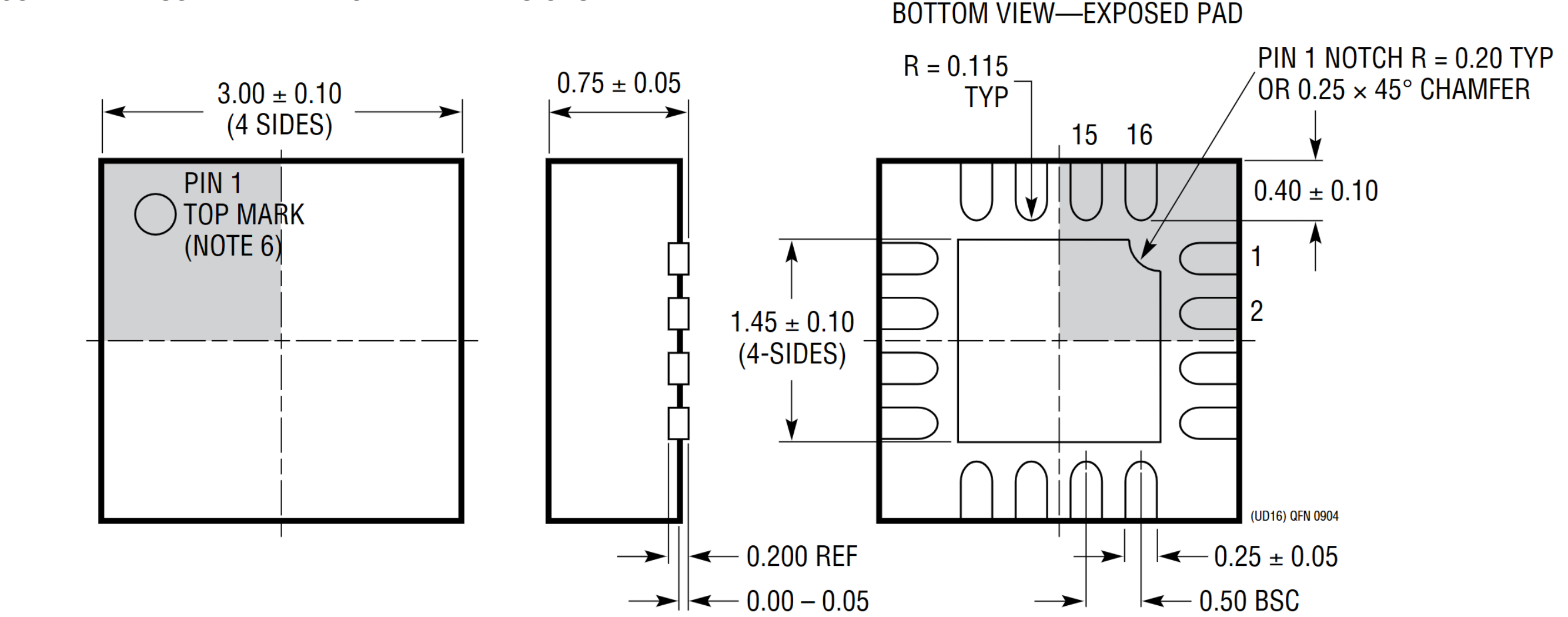

Package Description

16-Lead Plastic QFN (3mm × 3mm)

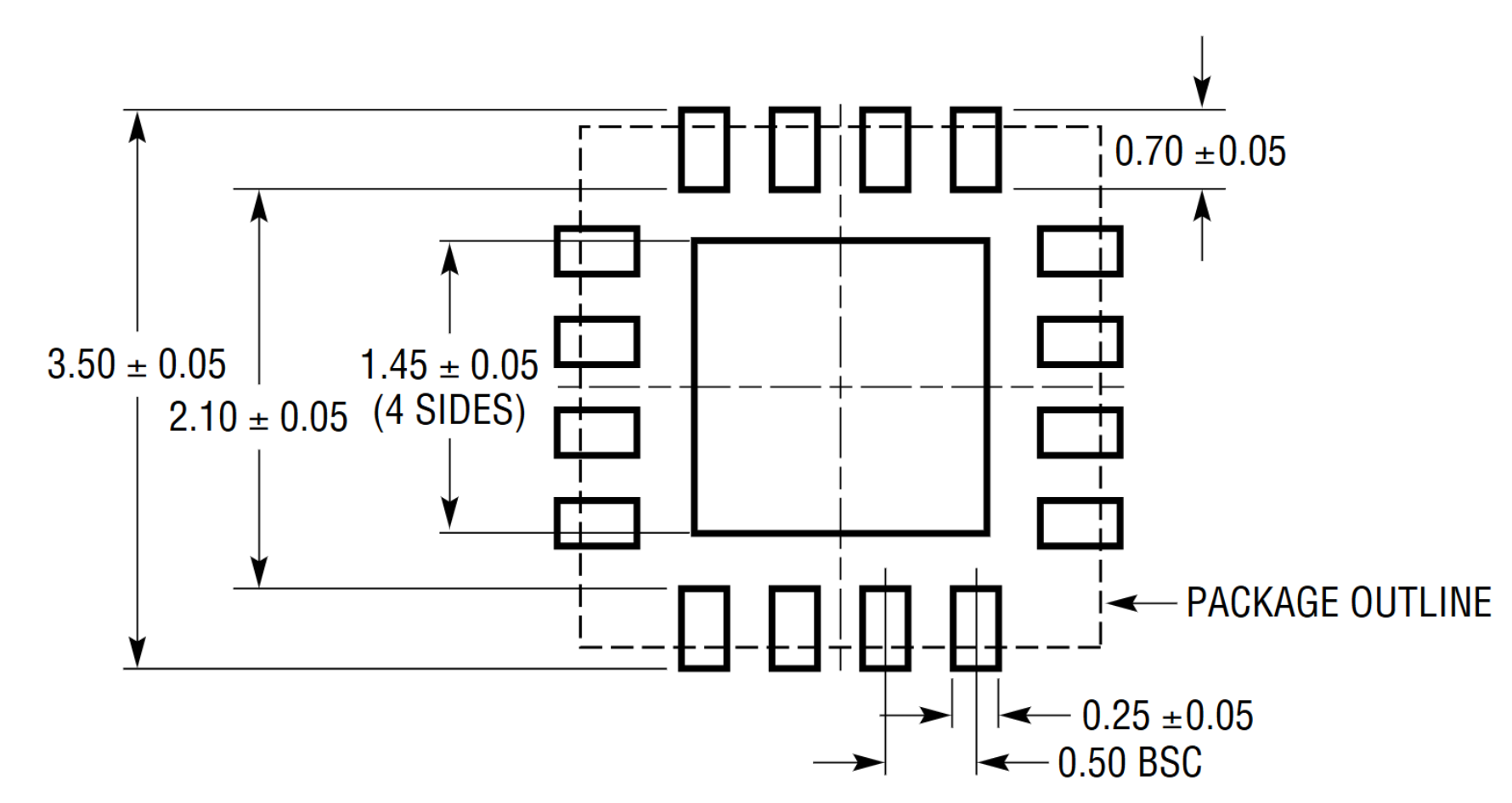

Recommended Solder Pad Pitch And Dimensions

Features of both components

The LT3756 is packed with several features that make it ideal for high-performance, energy-efficient designs:

· 3000:1 True Color PWM™ Dimming: This feature ensures smooth and flicker-free dimming of LEDs, making it especially valuable in applications where fine control over light intensity is required.

· Wide Input Voltage Range: It operates within an input voltage range of 6V to 100V, offering flexibility for a variety of applications.

· Output Voltage Up to 100V: Can regulate output voltage up to 100V, supporting high-power applications that require substantial voltage.

· Constant-Current and Constant-Voltage Regulation: The LT3756 can regulate current and voltage simultaneously, ensuring stable operation in a wide range of conditions.

· 100mV High Side Current Sense

· Drives LEDs in Boost, Buck Mode, Buck-Boost Mode, SEPIC or Flyback Topology

· Adjustable Frequency: 100kHz to 1MHz

· Open LED Protection

· Programmable Undervoltage Lockout with Hysteresis

· Improved Open LED Status Pin (LT3756-2)

· Frequency Synchronization (LT3756-1)

· PWM Disconnect Switch Driver

· CTRL Pin Provides Analog Dimming

· Low Shutdown Current: <1μA

· Programmable Soft-Start

· Thermally Enhanced 16-Lead QFN (3mm × 3mm) and MSOP Packages

· AEC-Q100 Qualified for Automotive Applications

Applications of LT3756

Given its robust features, the chip is ideal for a variety of high-power and current-regulated applications. Let's take a closer look at some of the most common applications where this series shines:

1. High Power LED Applications

The LT3756 series is particularly well-suited for driving high-power LEDs, where precise current regulation is paramount. LEDs often require a constant current to ensure optimal performance and longevity, and the LT3756’s constant-current mode allows it to precisely regulate the LED current, preventing overheating and reducing the risk of damage due to excessive current.

2. Current Limited Constant Voltage Applications

The ability to operate as a constant-voltage source while maintaining current regulation makes the LT3756 an ideal choice for applications that require current-limited power supplies. This is especially useful in battery charging and certain industrial applications where maintaining a stable voltage while limiting the current is crucial for the safety and performance of the system.

3. Battery Charging

Battery charging is another prime application for the LT3756 series. The device’s ability to operate in constant-voltage and constant-current modes ensures that batteries are charged efficiently without overcurrent or overvoltage conditions, both of which could damage the battery or reduce its lifespan. The wide input voltage range (6V to 100V) also makes it versatile for a range of battery types and charging configurations.

FAQ: Why Does Packaging Matter?

While the electrical performance and features of the two versions are identical, the choice of packaging can affect several factors in the manufacturing process, including:

1. Production Efficiency: Tape and reel packaging is more suited for automated processes, reducing labor costs and minimizing the risk of human error during assembly.

2. Handling and Storage: Components packed in tubes are generally easier to handle manually and are typically used in situations where smaller quantities are required, or when components need to be hand-placed.

3. Quantity Requirements: Tape and reel packaging is often more efficient for large-scale production runs because it minimizes the need for manual handling and simplifies the logistics of delivering parts to assembly lines.

Ultimately, the decision between the two versions depends on the specific needs of the manufacturer. If use the components in a low-volume, manual assembly environment, the tube-packaged LT3756EUD-2#PBF might be a better option. On the other hand, for high-volume production with automated placement, the LT3756EUD-2#TRPBF would be the preferable choice.

Conclusion

In summary, both the parts are essentially the same component, offering the same features and performance characteristics. The only difference lies in their packaging: the LT3756EUD-2#PBF comes in a tube format, while the LT3756EUD-2#TRPBF is pack in tape and reel. This difference in packaging determines the suitability of each part for different assembly and production environments.

Regardless of the packaging, the LT3756 family offers a robust and efficient solution for applications that require constant-current regulation, such as high-power LED drivers, battery charging systems, and current-limited constant voltage applications. With features like True Color PWM dimming, wide input and output voltage ranges, and constant-current/constant-voltage regulation, this series remains a versatile choice for power management designs.

By understanding the minor but important distinction in packaging, designers can select the most appropriate part for their production process, ensuring both efficiency and reliability in their final applications.

Related Parts

Part Number | Description |

36V, 1A (ILED), 2MHz, Step-Down LED Driver | |

LT3475 | Dual 1.5A (ILED), 36V, 2MHz Step-Down LED Driver |

LT3476 | Quad Output 1.5A, 36V, 2MHz High Current LED Driver with 1000:1 Dimming |

LT3477 | 3A, 42V, 3MHz Boost, Buck-Boost, Buck LED Driver |

LT3478/LT3478-1 | 4.5A, 42V, 2.5MHz High Current LED Driver with 3000:1 Dimming |

LT3486 | Dual 1.3A, 2MHz High Current LED Driver |

LT3496 | Triple 0.75A, 2.1MHz, 45V LED Driver |

1.5A, 2.5MHz, 45V LED Driver | |

LT3518 | 2.3A, 2.5MHz, 45V LED Driver |

LT3755/LT3755-1/LT3755-2 | 40V IN, 75V OUT, Full Featured LED Controller |

LTC®3783 | High Current LED Controller |

Product Catalog

Product Catalog