A 200 ohm resistor is a passive electronic component widely use in circuits to limit current, divide voltages, and protect components. Whether you are an electronics hobbyist, engineer, or educator, understanding the role, types, and specifications of a 200Ω resistor helps in selecting the right part for your applications. Here is the catalog:

1. What is a 200 Ohm Resistor?

2. Types of 200 Ohm Resistors And Comparing

3. 200 Ohm Resistor Color Code

4. Power Rating of a 200 Ohms Resistor

5. Applications of The Resistor 200 Ohm

6. Selecting The Right 200 Ohm Resistor & Real World Examples

1. What is a 200 Ohm Resistor?

An electronic component with a electrical resistance value of exactly 200 ohms, which means it offers 200Ω of opposition to the flow of electric current. According to Ohm’s Law (V = I R), when apply a voltage, this resistor controls the current that flows through a circuit.

This resistor ensures that components like LEDs, transistors, and microcontrollers receive the correct current to operate safely. In both analog and digital circuits, 200Ω use for protecting LEDs and ICs, creating voltage dividers, controlling current flow and signal filtering or termination. They are available in various types, tolerances, power ratings, and physical packages, making them suitable for both low-power hobby circuits and professional electronic systems.

2. Types of 200 Ohm Resistors And Comparing

Choosing the right type of 200Ω depends on factors like tolerance, stability, application, and cost. Here's a comparison of the most common types:

1. Carbon Film

Construction: A thin layer of carbon deposit on a ceramic substrate. Features: Moderate tolerance (±5% to ±10%), inexpensive and widely available, moderate temperature stability Advantages: Cost-effective, easy to find, good for general-purpose circuits. Common Uses: Basic electronics, hobby projects, prototyping.

2. Metal Film

Construction: Such as nickel-chromium is vacuum-deposit on a ceramic base. Features: High precision (±1%, ±0.5%, ±0.1%), low noise and better temperature coefficient, stable over time and frequency. Advantages: Accurate resistance, low noise, long-term reliability. Common Uses: Precision analog circuits, sensor interfaces, test and measurement equipment.

3. Metal Oxide Film

Construction: Made by depositing a metal oxide layer (like tin oxide) on a ceramic rod. Features: Good temperature stability, better high-voltage performance than metal film and flame-resistant. Advantages: High durability, better heat resistance and longer lifespan. Common Uses: Power supplies, industrial circuits, high-temperature environments.

4. Wire-Wound

Construction: A resistive wire (usually nickel-chromium) is wound around an insulating core. Features: Accurate (±0.1% or better), excellent heat dissipation, handles high power (up to 200W or more). Advantages: Ideal for high power applications, high stability, high surge tolerance. Common Uses: Motor controllers, power amplifiers, load banks.

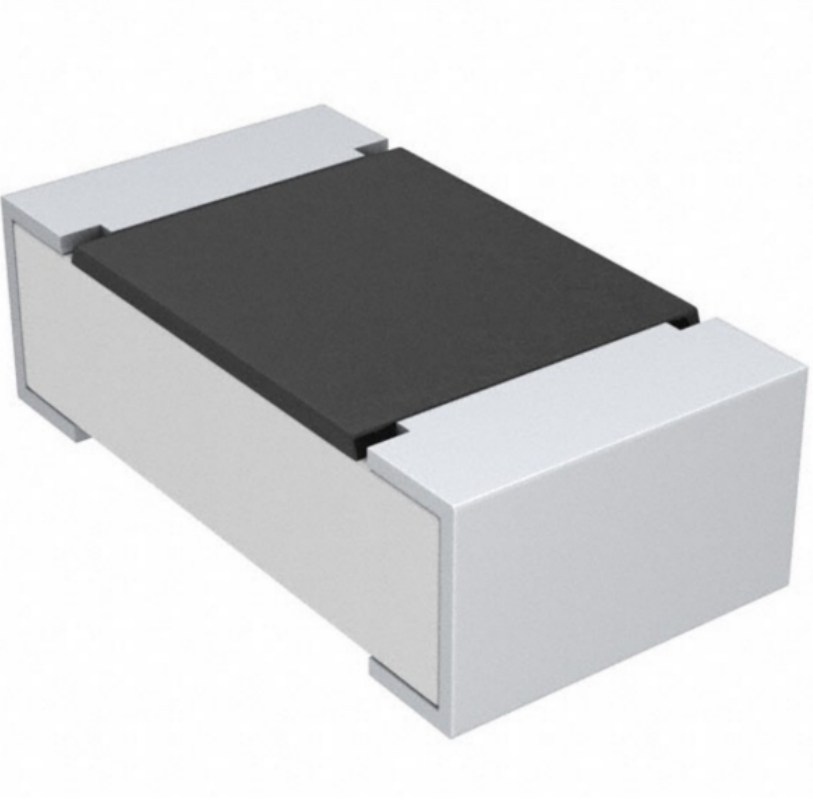

5. Surface Mount 200 Ohm Resistor SMD

Construction: Compact chip-style made with thick or thin film resistive layers. Features: compact and lightweight, automated PCB assembly compatible, resistance values marked in numerical codes. Advantages: Space-saving, soldered directly to PCB and available in a wide range of sizes (0201, 0402, 0603, 0805, etc.). Common Use in smartphones, laptops, and tablets, IoT and embedded systems, high-density circuit boards.

For high-precision applications, use metal film; for high-power circuits, choose wire-wound; for general electronics, carbon film suffices.

Type Comparing | Accuracy | Power Rating | Size | Cost |

Carbon Film | ±5–10% | Low | Through-hole | Low |

Metal Film | ±0.1–1% | Low–Medium | Through-hole | Medium |

Metal Oxide Film | ±1–5% | Medium–High | Through-hole | Medium |

Wire-Wound | ±0.1–5% | High (1–200W) | Through-hole | Higher |

SMD | ±0.1–5% | Low | Surface mount | Low–High |

3. 200 Ohm Resistor Color Code

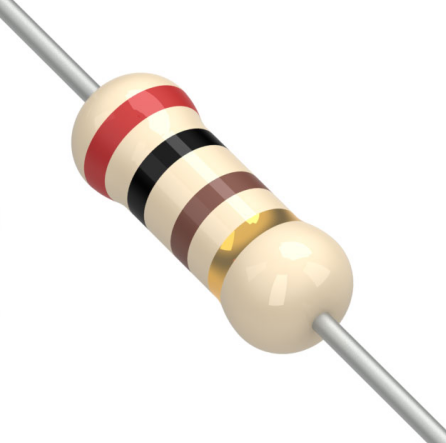

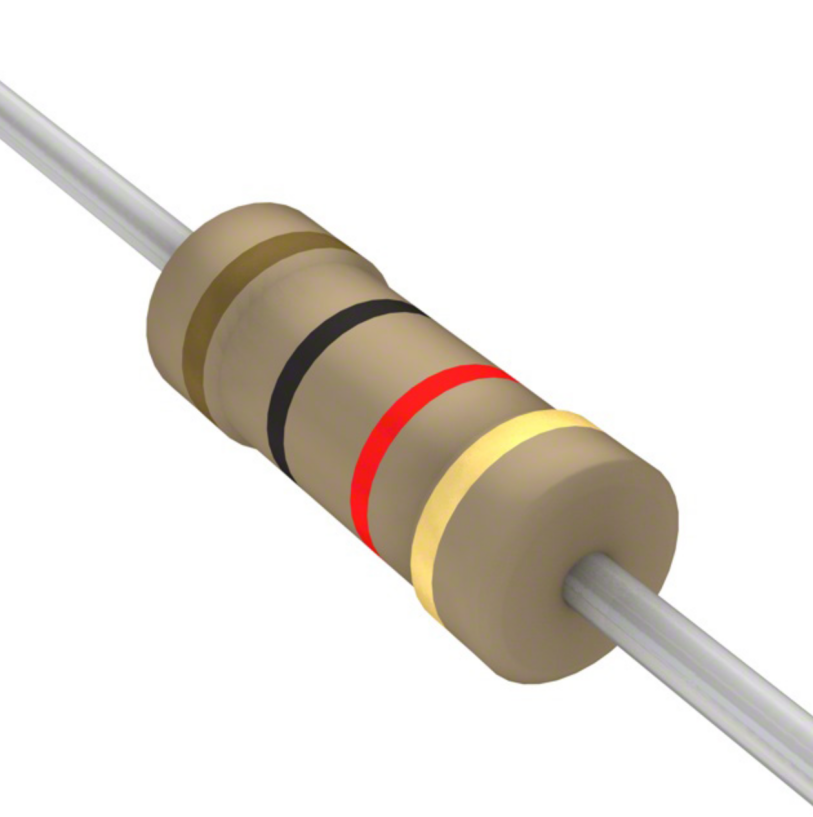

4-Band Color Code: Red - Black - Brown - Gold

Band Number | Colour | Value | Meaning |

1st-Band | Red | 2 | First-digit |

2nd-Band | Black | 0 | Second-digit |

3rd-Band | Brown | ×10 | Multiplier |

4th-Band | Gold | ±5% | Tolerance |

Result: 200Ω ±5% | |||

Reading a 4-band resistor involves identifying and interpreting the colored bands from left to right (hold the gold or silver tolerance band to the right).

First-Band: Red = 2 → This is the first-digit of the resistance value. Second-Band: Black = 0 → This is the second-digit of the resistance value. Third Band : Brown = ×10 → This is the multiplier (multiply the first two digits by 10). Fourth Band :

Gold = ±5% → This is the tolerance (acceptable resistance range). Final Calculation: (2 0) × 10 = 200 ohms. Tolerance = ±5%, which means the resistor's actual value can range from 190Ω to 210Ω.

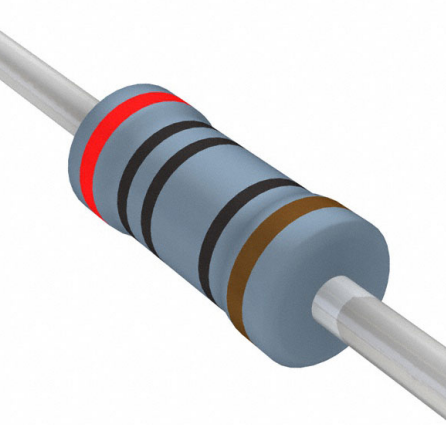

200 Ohm Resistor Color Code 5 Band:

Band Number | Color | Value | Meaning |

1st-Band | Red | 2 | 1st-digit |

2nd-Band | Black | 0 | 2nd-digit |

3rd-Band | Black | 0 | 3rd- digit |

4th-Band | Black | ×1 | Multiplier |

5th-Band | Brown | ±1% | Tolerance |

Result: 200Ω ±1% | |||

Color Code: Red – Black – Black – Black – Brown

When reading a 5-band resistor, follow these steps left to right, holding the resistor with the tolerance band (usually spaced slightly apart) on the right:

1st-Band : Red = 2 → First significant digit. 2nd-Band : Black = 0 → Second significant digit. 3rd-Band : Black = 0 → Third significant digit. 4th-Band : Black = ×1 → Multiplier. 5th-Band : Brown = ±1% → Tolerance. Final Calculation: (2 0 0) × 1 = 200 ohms. Tolerance = ±1%, so the actual value can vary between 198Ω and 202Ω.

Difference Between 4-Band and 5-Band Resistors

Feature | 4-Band Resistor | 5-Band Resistor |

Number of Bands | 4 (Color stripes) | 5 (Color stripes) |

Use For | General-purpose resistors | Precision resistors |

Significant Digits | 2 digits | 3 digits |

Multiplier | 3rd-band | 4th-band |

Tolerance Band | 4th-band | 5th-band |

Typical Tolerance | ±5% (Gold), ±10% (Silver) | ±1% (Brown), ±2% (Red), ±0.5% or less |

Example (200Ω) | Red - Black - Brown - Gold (±5%) | Red - Black - Black - Black - Brown (±1%) |

Accuracy | Lower (general tolerance) | Higher (tight tolerance) |

Key Differences:

Precision: 5-band resistors offer more accurate resistance values according to the third significant digit. Tolerance: 5-band types usually have tighter tolerance (±1%, ±0.5%) compared to 4-band ones (±5%, ±10%). Application: Use 4-band for simple circuits; use 5-band in sensitive or precise applications, such as sensors, measurement tools, or medical electronics.

6-Band Colors Code (with Temperature Coefficient):

Red - Black - Black - Black - Brown - Brown

Band Number | Colour | Value | Meaning |

1st-Band | Red | 2 | First digit |

2nd-Band | Black | 0 | Second digit |

3rd-Band | Black | 0 | Third digit |

4th-Band | Black | ×1 | Multiplier |

5th-Band | Brown | ±1% | Tolerance |

6th-Band | Brown | 100 ppm/°C | Temperature Coefficient |

Result: 200Ω ±1% 100 ppm/°C | |||

Temperature Coefficient (Tempco) indicates how much resistance changes with temperature.

Brown (100 ppm/°C) means the resistor changes by 0.02 ohms per 1°C rise (for a 200Ω ).

How to Read a 6-Band 200 Ω colour coding?

A 6-band read similarly to a 5-band, with the 6th band showing the temperature coefficient (Tempco).

1st-Band : Red = 2 → First-digit. 2nd-Band : Black = 0 → Second-digit. 3rd-Band : Black = 0 → Third-digit. 4th-Band : Black = ×1 → Multiplier. 5th-Band : Brown = ±1% → Tolerance. 6th-Band : Brown = 100 ppm/°C → Temperature coefficient.

Final Calculation: (200) × 1 = 200-ohms. Tolerance = ±1% → Actual value can be from 198Ω to 202Ω. Temperature Coefficient = 100 ppm/°C. Resistance may change by 0.02 ohms for every 1°C change in temperature

This type is use in precision circuits where stability over temperature is critical, such as in measuring instruments, sensors, and medical equipment.

Feature | 4-Band | 5-Band | 6-Band |

Number of Bands | 4 | 5 | 6 |

Significant Digits | 2 digits | 3 digits | 3 digits |

Multiplier Band | 3rd-band | 4th-band | 4th-band |

Tolerance Band | 4th-band | 5th-band | 5th-band |

Temperature Coefficient Band | None | None | 6th-band (ppm/°C) |

Typical Tolerance | ±5%, ±10% | ±1%, ±2%, ±0.5% | ±0.1% to ±1% |

Temperature Stability | Basic | Better | Best (with tempco specified) |

Precision Level | General purpose | Precision/resistors with tighter tolerance | High precision with temperature compensation |

Common Uses | Everyday electronics | Sensitive, precision circuits | Precision measurement & temperature-sensitive applications |

Colors Codes | Red – Black – Brown – Gold | Red – Black – Black – Black – Brown | Red – Black – Black – Black – Brown – Brown |

Key Differences Explained:

4-Band: Simpler, easier to read; mainly for general use with moderate tolerance (usually ±5%). Uses 2 digits for resistance.

5-Band: More precise; uses 3 digits for resistance, giving more accurate values and tighter tolerances (±1% or better). Prefer for sensitive or critical circuits.

6-Band: Adds a 6th-band that indicates the temperature coefficient — how much resistance changes with temperature (ppm/°C). Ideal for applications where require stability over temperature.

Band Number | 4-Band | 5-Band | 6-Band |

1st-Band | 1st-digit | 1st-digit | 1st-digit |

2nd-Band | 2nd-digit | 2nd-digit | 2nd-digit |

3rd-Band | Multiplier | 3rd-digit | 3rd-digit |

4th-Band | Tolerance | Multiplier | Multiplier |

5th-Band | N/A | Tolerance | Tolerance |

6th-Band | N/A | N/A | Temperature coefficient (ppm/°C) |

In 4-band, the 3rd band is the multiplier, and the 4th-band is the tolerance. In 5-band, add an extra digit for higher precision: the 3rd-band is a significant digit, the 4th-band is the multiplier, and the 5th-band is tolerance. In 6-band, the layout is the same as 5-band, but a 6th-band indicates the temperature coefficient.

4. Power Rating of a 200 Ohms Resistor

Determine how much power (in watts) a resistor can safely dissipate as heat without damage. Choosing the correct wattage is necessary for circuit reliability and safety.

200 ohm 1/4 watt resistor: Standard low-power resistor, ideal for small signal circuits and LED current limiting. Common in hobby electronics.

200 ohm 1/2 watt resistor: Slightly higher power handling, use in sensors, low-power amplifiers, and small circuits needing more durability.

200 ohm 1 watt resistor: Moderate power rating for more demanding circuits, such as biasing transistors or small load resistors in power supplies.

200 ohm 2 watt resistor: Use where require more heat dissipation, like in motor controllers or audio equipment.

200 ohm 5 watt resistor: Suitable for power regulation, resistive loads in power supplies, or industrial circuits.

200 ohm 10 watt resistor: High power resistor, often wire-wound, use in power amplifiers, voltage regulation, and braking circuits.

200 ohm 20 watt resistor: Heavy-duty resistor for high-current applications and industrial use.

200 ohm 25 watt resistor: High power wire-wound type, typically for large power electronics and load banks.

200 ohm 100 watt resistor: High power resistor, use in specialized applications such as RF dummy loads, large power testing, or power electronics.

200 ohm 200 watt resistor: High power rating, for heavy industrial loads, test equipment, and large current dissipation scenarios.

Tips for Selecting Power Rating:

Calculate power dissipation: P = I² × R or P = V² / R. Always choose a resistor with a power rating at least 2x higher than the calculated dissipation to ensure safety and longevity. Higher power resistors tend to be physically larger and may require heat sinking.

5. Applications of The Resistor 200 Ohm

The 200R-resistor is a versatile and widely use component in many electronic circuits. Its ability to precisely limit current and drop voltage makes it indispensable across a range of applications, from simple hobby projects to complex industrial systems. Here are some of the most common uses:

1. LED Current Limiting: One of the most frequent uses is in series with an LED (Light Emitting Diode) to limit the current flowing through it. This prevents the LED from drawing too much current, which can otherwise damage it. For typical 5V circuits, a 200Ω helps maintain safe current levels for standard LEDs.

2. Voltage Dividers: In many electronic designs, a 200-ohm is part of a voltage divider circuit. Voltage dividers use two or more resistors to produce a specific output voltage lower than the input voltage. This is necessary in sensor interfaces, analog signal conditioning, and microcontroller input scaling.

3. Signal Conditioning and Filtering: Use in combination with capacitors and inductors to create filters that smooth or shape electrical signals. These are vital in audio circuits, RF systems, and sensor signal processing to remove noise and unwanted frequencies.

4. Pull-Up and Pull-Down Resistors: In digital electronics, 200 ohm can act as pull-up or pull-down resistors to ensure logic inputs settle at defined voltage levels (high or low) when switches or buttons are open. This prevents floating inputs that could cause erratic circuit behavior.

5. Sensor Biasing: Certain sensors require a specific biasing current or voltage to operate correctly. A 200 ohm can use to set this bias precisely, enabling accurate sensor readings in temperature sensors, photodiodes, and other analog sensors.

6. Current Sensing: By placing a 200 ohms resistors in series with a load, you can measure the voltage drop across it to determine the current flowing through the circuit. This method is widely use in power management and battery monitoring systems.

7. Protective Applications: Can protect sensitive components like microcontrollers and integrated circuits from voltage spikes and surges by limiting current or acting as a part of snubber circuits.

8. Power Supply Regulation: In power supply circuits, help regulate current and voltage levels, serving as load resistors or part of feedback mechanisms to maintain stable operation.

9. Industrial and Automotive Electronics: High-power resistors 200 ohm use in industrial control systems, motor drives, and automotive electronics where require reliable current control and voltage division under harsh operating conditions.

6. Selecting The Right 200 Ohm Resistor & Real World Examples

To choose the right circuit, consider these criteria:

Factor | Options/Details |

Type | Carbon Film, Metal Film, Wire-wound, etc. |

Power Rating | 1/4W, 1/2W, 1W, 10W, 100W, etc. |

Tolerance | ±5%, ±1%, ±0.1% (precision metal film) |

Packaging | Through-Hole (Axial, Radial) or SMD (0402, 0603) |

Example 1. LED Series Resistor: Carbon film with power rating 1/4W. Application is limit current to an LED from 5V supply.

Example 2. Audio Crossover Network: Metal film with power rating 1W. Application is forms part of a low-pass filter.

Example 3. Load Resistor in Power Supply Test: Wire-wound with power rating 100W. Application is discharges stored energy in capacitors.

7. 200 Ohm Resistor Price

The price can vary based on several factors such as:

Type of resistor (carbon film, metal film, metal oxide, wire-wound, SMD). Power rating (1/4 watt, 1/2 watt, 1 watt, etc.). Tolerance level (±5%, ±1%, ±0.1%, etc.). Quantity purchased (bulk vs. single units). Brand and quality.

Type & Rating | Approximate Unit Price (USD) |

1/4W Carbon Film | $0.001 – $0.005 |

1/2W Metal Film | $0.003 – $0.010 |

1W Wire-Wound | $0.010 – $0.030 |

10W Wire-Wound | $0.050 – $0.10 |

200Ω 100W Power Resistor | $0.30 – $1.00 |

SMD 0201, 0402, 0603, 0805, 1206 | $0.0005 – $0.003 |

Buying in bulk significantly reduces cost per component. Higher tolerance and power ratings usually mean a higher price. For precision or critical applications, recommend investing in quality brand-name resistors.

8. Frequently Asked Questions

1. What is the color code for 220 ohm resistor?

The 220 ohm resistor’s standard 4-band colour codes is Red – Red – Brown – Gold. The first-band “Red” stands for 2, the-second “Red” is also 2, the third-band “Brown” is the multiplier (×10), so 22 × 10 = 220 ohms. The last band “Gold” indicates a tolerance of ±5%. This colors coding helps quickly identify the resistor’s value and precision, which is necessary for assembling and troubleshooting electronic circuits. Also have 5-band(red - black - black - black - brown) and 6-band versions with tighter tolerances and temperature coefficients for precision uses.

2. How to tell a 220 ohm resistor?

To identify a 220-ohm, look for its colored bands. In the common 4-band version, the bands read Red – Red – Brown – Gold. The first two bands give the digits (2 and 2), the third is the multiplier (brown = ×10), and the last is tolerance (gold = ±5%). Use a multimeter to measure resistance for confirmation. The physical size and power rating may vary, so always double-check. For 5 or 6-band resistors, additional bands provide more precision. Visual identification combined with measurement ensures you’re using the correct resistor.

3. Is a 220 ohm resistor enough for LED?

Commonly use 220Ω as a current-limiting resistor for standard LEDs powered from 5V circuits. It typically allows about 20mA current, which is safe for most indicator LEDs. However, the exact resistance value depends on the LED’s forward voltage and desired current. Using a 220 Ω protects the LED from drawing too much current, preventing damage and extending its lifespan. For lower voltage or different LEDs, you may need to calculate the correct resistance value. In many hobby projects, 220 ohms is a convenient standard for reliable LED operation.

4. What is the power rating of a 220 ohm resistor?

The most common power rating is 1/4 watt (0.25W), suitable for typical low-power electronic circuits such as LED current limiting or signal conditioning. Sometimes, use 1/2 watt (0.5W) if expect slightly more heat dissipation. For higher power applications, wire-wound or metal oxide resistors with ratings from 1 watt up to several watts exist, but these are less common for 220R values in typical electronics. Always choose a circuit with a power rating exceeding the calculated dissipation to ensure safe and reliable operation.

5. Do I need to add resistors for LED?

Yes, resistors are necessary for LEDs to control the current passing through them. LEDs have low internal resistance and can draw excessive current, which may quickly damage or destroy them. Adding a component in series limits current to a safe level, protecting the LED and the power source. The resistance value depends on the supply voltage, LED forward voltage, and desired current. Without this or appropriate current limiting, the LED can overheat and fail. Have to select the proper circuit for longevity and consistent LED brightness.

6. What is the difference between a 200 ohm resistor and a 220 ohm resistor?

The difference lies mainly in their resistance values: 200 ohms versus 220 ohms, which is a 10% variation. This affects the current flow and voltage drop in a circuit. A 220Ω limits current slightly more than a 200Ω. In many applications, this difference is minor and both can use interchangeably without significant impact. However, for precision circuits or when need exact current limiting(e.g., with LEDs or sensors), choosing the correct resistance value is important. Tolerance and power ratings also affect performance.

7. How do I choose the correct power rating for a 200 ohm resistor in my project?

To choose the right power rating, first calculate the power dissipated using P = I² × R or P = V² / R. This tells you how much heat the resistor will generate under normal operation. Then, select a circuit with a power rating at least twice that value to ensure safety and reliability. For example, if your calculation shows 0.1 watt, choose a 1/4 watt resistor or higher. Also consider the resistor’s size, tolerance, and operating environment (temperature, airflow). Proper power rating prevents overheating and premature failure.

8. Where can I find a 200 ohm resistor?

You can find 200-ohm at a variety of places. Local electronics or hobby stores typically stock common resistance values, including 200 Ω. Online electronics distributors such as Orwintech offer a wide selection with detailed specs, including tolerance and power ratings. In bulk at lower prices. For surface mount versions, look for reels or tape packaging. Always check the resistor specs to ensure they meet your project requirements.

9. What is a 220 ohm resistor used for?

Widely use to limit current in LED circuits, protecting LEDs from excess current that could cause damage. Beyond LEDs, use in voltage divider circuits, pull-up/pull-down resistor configurations in digital electronics, and signal conditioning applications. It provides moderate resistance suitable for low to medium power circuits. Its availability and versatility make it common in hobby electronics, prototyping, and many industrial applications where precise current limiting and voltage dropping are necessary.

Conclusion

The 200 ohm resistor is a widely applicable component in modern electronics, valued for its current-limiting and voltage-controlling abilities. With multiple types, power ratings, and tolerance options, it is necessary to select the right version based on your circuit’s needs. Whether you're building a simple LED circuit or designing a complex industrial control board, the 200Ω resistor remains a reliable workhorse.

Read More:

1. Complete Guide to the 220 Ohm Resistor

HOT NEWS

The 0402 Resistor: A Comprehensive Guide

0402 Resistor

2025-05-06

Understanding A 0603 Resistor

0603 resistor,dimensions,marking code, values

2025-05-29

What Is A 1206 Resistor?

1206 resistor dimensions,footprint,value

2025-06-05

What is 10k Ohm Resistor?

10k resistor 10k resistor color code

2025-05-14

Everything You Need To Know About ARE1309 Relay

2025-04-23

MT3608 Boost Converter - An In-Depth Guide

MT3608 Boost Converter

2025-09-04

What Is The 1K Ohm Resistor?

1k ohm resistor and color code

2025-05-21

Guide To The AMS1117 Voltage Regulator

AMS1117 Voltage Regulator Circuit

2025-08-17

2512 Resistor - A Comprehensive Guide

2512 Resistor

2025-08-13

What is 100 Ohm Resistor And Color Code?

100 ohm resistor color code

2025-05-17

Product Catalog

Product Catalog