20K ohm resistor widely use in signal conditioning, voltage dividers, filters, sensors, and low-power electronic circuits. Its moderate resistance value makes it a reliable choice for limiting current, setting biasing levels, and stabilizing sensitive analog and digital components. This guide explains what a 20K resistor is, its specifications, types, color codes, applications, comparisons, and FAQs.

1. What is a 20K Ohm Resistor?

2. Key Specifications of a Resistor 20K Ohm

3. Common Types of 20K Ohm Resistors

4. Applications of the 20K Ohms Resistor

5. 20K Ohm Resistor Color Code

6. 20K Resistor vs. Other Common Resistors (10K, 1K)

8. Frequently Asked Questions about 20K Ohm Resistors

What is a 20K Ohm Resistor?

A 20K resistor is an electronic component that provides 20,000 ohms of resistance to control or limit current flow in a circuit. It commonly use in voltage dividers, signal conditioning, sensor interfaces, pull-up or pull-down networks, and timing circuits. With its moderate resistance value, it helps reduce current consumption while maintaining stable voltage levels. A 20 K resistor can make from carbon-film, metal film, ceramic, or thick-film SMD materials, and it is available in various wattage ratings such as 1/4W, 1/2W, 1W, and 2W. It widely use in analog and digital electronics.

Key Specifications of a Resistor 20K Ohm

Power Rating

20K Ohm 1/4 Watt Resistor

A 20K 0.25W resistor is the most common type used in small signal circuits, sensors, voltage dividers, and microcontroller applications. It can safely dissipate 0.25 watts of power and is ideal for low-current, low-voltage electronics.

20K Ohm 1/2 Watt Resistor

20K 1/2W handles 0.5 watts, offering better heat tolerance than 1/4W types. It use in higher-voltage dividers, moderate-power filters, and circuits requiring more thermal stability.

20K Ohm 2 Watt Resistor

20K 2W can dissipate 2 watts, suitable for power supplies, amplifiers, and circuits where higher currents or voltages are present. It offers improved durability and heat resistance.

20K Ohm 5 Watt Resistor

20K 5W is a high-power component used in industrial equipment, motor control, braking circuits, and power regulation systems. With 5 watts of dissipation, it can withstand heavy loads and elevated temperatures.

Tolerance of 20K Ohms Resistor

A 20 K ohm resistor is available in a wide range of tolerance levels, determining how close the actual resistance is to the labeled value. Ultra-precision types offer tight tolerances such as 0.001%, 0.005%, 0.01%, 0.02%, and 0.05%, used in instrumentation, calibration, and high-accuracy analog circuits. Moderate-precision tolerances such as 0.1%, 0.2%, 0.25%, and 0.5% are common in audio, sensors, and stable control circuits. General-purpose resistors typically use 1%, 2%, 5%, or 10%, suitable for everyday electronics where exact values are not critical.

Tolerance Range | Actual Resistance Range (Ω) |

±0.001% | 19,999.8~20,000.2 |

±0.005% | 19,999~20,001 |

±0.01% | 19,998~20,002 |

±0.02% | 19,996~20,004 |

±0.05% | 19,990~20,010 |

±0.1% | 19,980~20,020 |

±0.2% | 19,960~20,040 |

±0.25% | 19,950~20,050 |

±0.5% | 19,900~20,100 |

±1% | 19,800~20,200 |

±2% | 19,600~20,400 |

±5% | 19,000~21,000 |

±10% | 18,000~22,000 |

Table: Key Specifications & Typical Values

Description | Typical Values | Application |

Power Rating | 1/4W, 1/2W, 1W, 2W, 5W | Defines the maximum power the circuit can safely dissipate without overheating. Lower power ratings use in low-power signal circuits, while higher power ratings use in power supplies, amplifiers, and motor control applications. |

Tolerance | 0.01%, 0.05%, 0.1%, 0.5%, 1%, 5% | Tolerance determines the allowable deviation from the nominal value. High-precision applications, such as instrumentation and measurement, require tight tolerance resistors (e.g., 0.1%), while general-purpose circuits use 1% or 5%. |

Temperature Coefficient (TCR) | ±5, ±10, ±25, ±50, ±100, ±200 ppm/°C | TCR defines how much the resistance changes with temperature. Need low TCR values for high-precision, temperature-sensitive applications like sensor circuits, whereas higher TCR resistors are acceptable in general-use cases. |

Material | Carbon-Film, Metal-Film, Thick Film (SMD), Wirewound, Ceramic | Material choice impacts the resistor’s precision, cost, stability, and power handling. Metal film types offer higher accuracy and stability, while carbon film is more economical for general applications. Wirewound use for high-power applications. |

Operating Temperature Range | -55°C ~ +155°C (metal film), -40°C ~ +125°C (carbon film), -55°C ~ +200°C (wirewound) | The operating temperature range ensures that the circuit remains stable and functional under various environmental conditions. Wide-range resistors use in automotive, industrial, and military applications, while standard ranges are suitable for consumer electronics. |

Voltage Rating | 50V ~ 250V depending on package and wattage (typical: 100V for 1/4W, 200V for 1/2W) | Voltage rating indicates the maximum voltage the resistor can withstand without breaking down. Higher voltage ratings use in power supplies, high-voltage signal circuits, and industrial applications, while lower voltage ratings use in standard consumer devices. |

Common Types of 20K Ohm Resistors

Carbon Film Resistor

Made by applying a thin film of carbon to a ceramic substrate. These resistors typically have low precision, with tolerance values ranging from ±5% to ±10%. Their stability is moderate, and they are cost-effective, making them suitable for general-purpose applications. They commonly use in low-cost electronics, LED current limiting, basic signal processing, and hobbyist projects.

Metal Film Resistor

Made from a thin layer of a nickel-chromium alloy. These resistors offer high precision, with tolerance values ranging from ±0.1% to ±1%. They also provide excellent stability, with low noise and long-term reliability. Although they are more expensive than carbon film types, they widely use in precision circuits, audio equipment, sensors, and high-quality analog applications where stability and low noise are crucial.

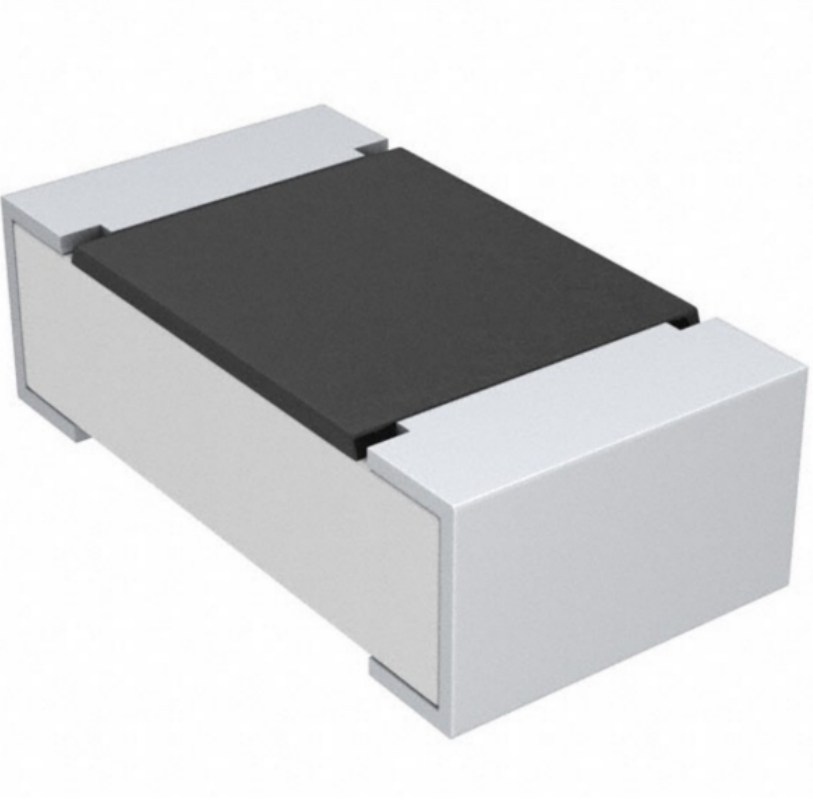

Surface Mount 20K Ohm SMD Chip Resistor

A surface mount 20K chip resistor, available in the different packages, such as 0402, 0603, 0805, 1206, typically make with a thick or thin film on a ceramic substrate. These resistors usually have medium precision, with tolerances ranging from ±1% to ±5%. Their stability is moderate, and they are relatively inexpensive. These resistors commonly use in compact and space-efficient designs such as modern circuit boards, mobile devices, IoT applications, consumer electronics, and power supply circuits.

20K Ohm Ceramic Resistor

A ceramic resistor features a ceramic substrate with a resistive coating. It can offer low to medium precision depending on the design, but it excels in stability, particularly in high-temperature environments. Ceramic resistors are resistant to high temperatures, making them suitable for applications that require heat tolerance. These types typically use in power supply circuits, RF circuits, and industrial applications where temperature resistance is necessary.

Comparison Table: Materials vs. Features

Material | Precision | Stability | Typical Applications |

Carbon Film | Low | Medium | Hobby circuits, LED limiting |

Metal Film | High | High | Audio, instrumentation |

Thick-Film SMD | Medium | Medium | Consumer electronics |

Ceramic | Low | High | RF, high-temp circuits |

Applications of the 20K Ohms Resistor

Voltage Dividers

Often use in voltage divider circuits to reduce higher voltages to a lower, more manageable level. It helps create reference voltages for sensors, microcontrollers, or analog-to-digital converters (ADCs), enabling precise voltage measurements in many electronic projects.

Pull-up and Pull-down Resistors

In digital circuits, can use 20K ohm as a pull-up or pull-down resistor. It ensures that the input pins of microcontrollers, logic gates, or other digital components are at a defined logic level (high or low), preventing them from floating and causing erratic behavior or incorrect readings.

Signal Filtering

Commonly use in RC (resistor-capacitor) filters to remove unwanted noise and smooth signals in audio, sensor, and communication circuits. It can filter out high-frequency noise from power supplies or stabilize signals in analog circuits.

Current Limiting

In circuits with components like LEDs, use the 20K to limit the amount of current flowing through the component. This prevents the component from burning out as excessive current, especially in low-voltage applications where precision is important.

Biasing Transistors and Op-Amps

Use in biasing networks to set the operating point of transistors and operational amplifiers (op-amps) in amplification circuits. This ensures that the components function within their optimal operating range, providing stable and linear amplification of signals.

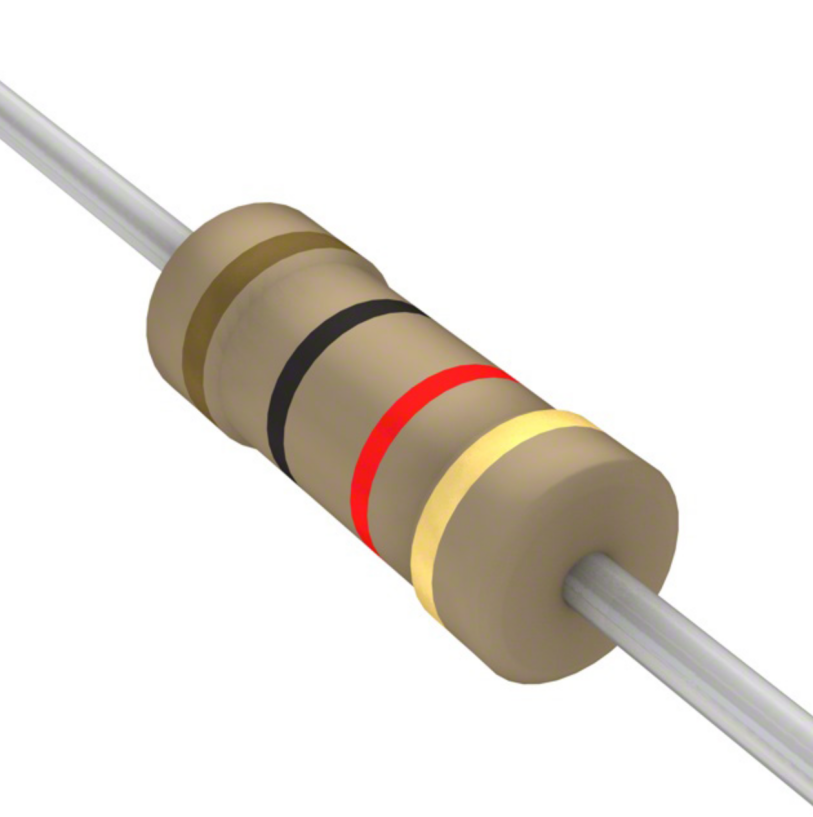

20K Ohm Resistor Color Code

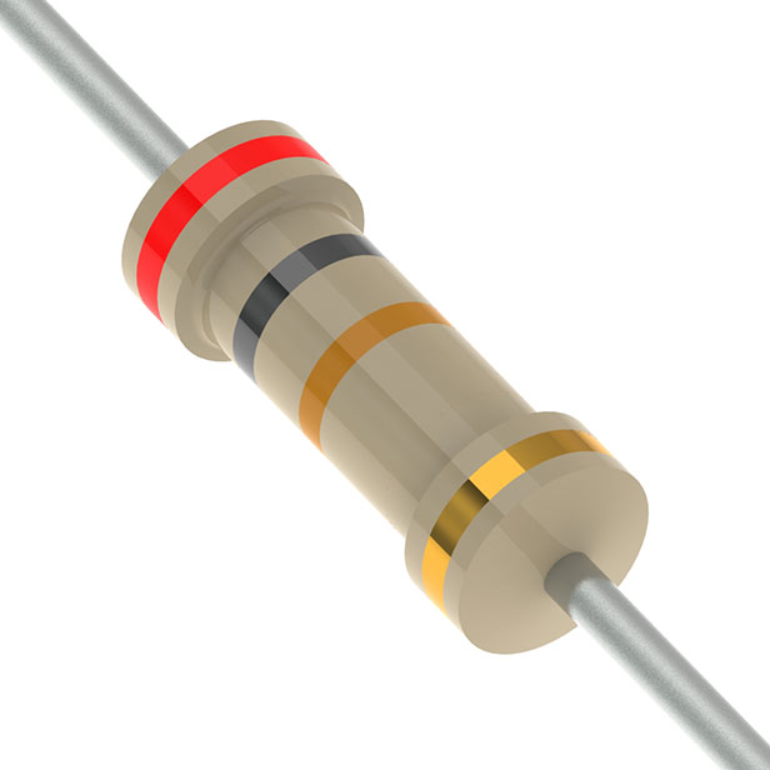

4 Band Colour Coding

Band | Color | Explanation |

First | Red | First-digit (2). |

Second | Black | Second-digit (0). |

Third | Orange | Multiplier (×1,000). |

Fourth | Gold | Tolerance (±5%). |

The colour code for a 20 K ohm with a 4-band configuration is as follows:

First-Band (Red): Represents the first-digit, which is 2.

Second-Band (Black): Represents the second-digit, which is 0.

Third-Band (Orange): Represents the multiplier, which is 10³ or 1,000.

Fourth-Band (Gold): Indicates tolerance, which is ±5%.

So, the 20K ohms resistors with a 4-band colors are read as 20 × 1,000 = 20,000 ohms (20K), with a tolerance of ±5%.

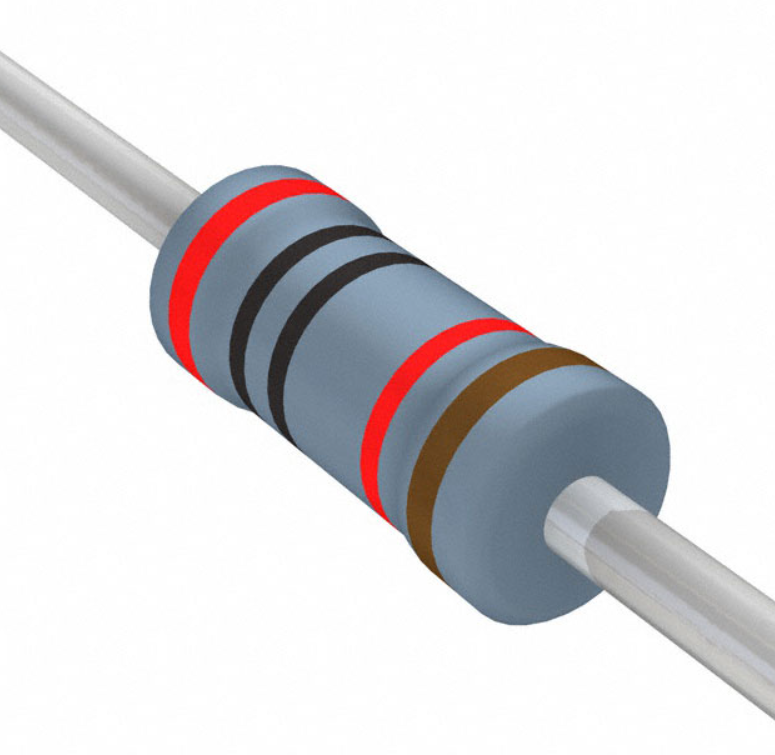

20K Ohm Resistor Color Code 5 Band

Band | Color | Explanation |

First | Red | First-digit (2). |

Second | Black | Second-digit (0). |

Third | Black | Third-digit (0). |

Fourth | Red | Multiplier (×100). |

Fifth | Brown | Tolerance (±1%). |

Explanation of Each Band:

First Band (Red): Represents the first-digit of the value, which is 2.

Second Band (Black): Represents the second-digit, which is 0.

Third Band (Black): Represents the third-digit, which is 0.

Fourth Band (Red): Represents the multiplier (×100), meaning the value of the resistor multiply by 100.

Fifth Band (Brown): Represents the tolerance, indicating the resistor’s actual value can vary by ±1% from the marked value.

20K Resistor vs. Other Common Resistors (10K, 1K)

Feature | 20KΩ | 10KΩ | 1KΩ |

Resistance | Highest | Medium | Lowest |

Current Flow (same voltage) | Lowest current | Medium current | Highest current |

Typical Uses | ADC dividers, pull-ups, filters, precision circuits | Sensors, timing, MCU inputs | LED limiting, high-current limiting |

Power Dissipation (same current) | Highest (P = I²R) | Medium | Lowest |

Precision Availability | High | High | High |

Higher resistance reduces current flow, making the 20KΩ suitable for low-power and precision signal conditioning.

20K Ohm Variable Resistor

A 20K ohm variable resistor, often referred to as a potentiometer, is an adjustable type that allows you to manually vary its resistance from 0 up to 20,000 ohms (20KΩ). This type of resistor has three terminals: two fixed terminals connected to a resistive element and a third terminal connected to a movable wiper that slides along the resistive track to adjust the resistance.

Key Features:

Resistance Range: It can vary from 0 to 20K ohms, providing fine control over resistance within this range.

Adjustment Mechanism: The wiper (the adjustable part) allows users to increase or decrease resistance by rotating a knob or turning a screw.

Precision: Potentiometers typically offer moderate precision, depending on the quality and type (e.g., 1%, 2%, or better tolerance).

Power Rating: Most potentiometers rate for low power, typically up to 0.25W to 0.5W, depending on the model.

Applications:

Volume Control: Potentiometers commonly use as volume controls in audio equipment, allowing you to adjust the signal strength.

Brightness or Contrast Adjustment: Used in devices like monitors and displays to adjust the brightness or contrast levels.

Sensor Calibration: They use in sensors to calibrate or adjust the sensor's output, like in temperature or pressure sensors.

Position Sensing: In motor control systems, potentiometers often use for measuring the position of a moving part or adjusting feedback loops.

Voltage Divider: In circuits where a fixed voltage needs to vary, often use a 20K potentiometer to create a variable voltage divider.

Types of Potentiometers:

Rotary Potentiometer: The most common type, where the wiper adjust by rotating a knob.

Linear Potentiometer: The wiper slides along a resistive track, providing linear control of resistance.

Digital Potentiometer: Used in advanced circuits, controlled electronically rather than manually.

Frequently Asked Questions about 20K Ohm Resistors

Is 20 mega ohm resistor 20k?

No, a 20 mega ohm (20MΩ) resistor is much larger than a 20KΩ. 20MΩ equals 20,000,000 ohms, while 20KΩ is 20,000-ohms. Using the wrong order of magnitude in a circuit can drastically reduce current flow or prevent the circuit from functioning correctly, so always check the resistance value before use.

What is the color code for a 20K ohm resistor?

The 4-band color code for 20KΩ is Red-Black-Orange-Gold (20,000 ohms, ±5% tolerance). The 5-band colour code is Red-Black-Black-Red-Brown (20,000 ohms, ±1% tolerance). The first two or three bands represent digits, the next is the multiplier, and the last band shows tolerance. This helps identify resistor values quickly without measurement.

How does a 20k resistor compare to a 10k resistor in a circuit?

A 20KΩ has double the resistance of a 10KΩ resistor, meaning it allows half the current for the same voltage. It dissipates less power at the same current and often use where need higher resistance for voltage dividers, pull-ups, or timing circuits. Choosing between them depends on desired current, voltage drop, and signal requirements.

What is the common power rating for a 20k ohm resistor?

Common power ratings for 20KΩ are 1/4W, 1/2W, 1W, 2W, and 5W, depending on the circuit’s current and voltage. Lower-power ratings like 0.25W are suitable for signal circuits, while higher ratings like 2W or 5W use in power supplies or industrial applications to prevent overheating and ensure reliability.

Can a 20k resistor be used as a pull-up or pull-down resistor?

Yes, a 20KΩ commonly use as a pull-up or pull-down resistor in digital circuits. It provides a defined logic level at input pins without drawing excessive current. Choose the value to balance between preventing floating inputs and minimizing power consumption, making it ideal for microcontrollers and logic devices.

What are the common materials used to make 20k ohm resistors?

Common materials for 20KΩ include carbon-film, metal-film, thick film (SMD), wirewound, and ceramic. Carbon film is low-cost and general-purpose, metal film offers high precision and stability, SMD packages are compact for PCBs, wirewound is high-power capable, and ceramic resistors handle high temperature or industrial conditions.

How do I choose between a carbon film and a metal film 20k ohm resistor?

Choose carbon film if you need a low-cost, general-purpose resistor with moderate precision. Opt for metal film when require high accuracy, low noise, and long-term stability, such as in audio, sensor, or precision analog circuits. Consider the circuit tolerance, operating temperature, and budget when making the choice.

What happens if resistor is wrong?

Using the wrong resistor value can alter current flow, voltage levels, and power dissipation. Too high resistance will prevent a device from operating; too low can overload components, causing overheating or damage. Wrong tolerance or power rating can reduce circuit reliability. Always verify resistance, tolerance, and wattage before installation to prevent malfunctions.

Where to Purchase 20k Ohm Resistors?

Can purchase 20KΩ from electronics suppliers like Orwintech Electronics. They are available in various types: carbon-film, metal-film, SMD, and wirewound. Check specifications such as tolerance, power rating, and package before buying. Bulk packs or individual resistors are available for hobbyists and industrial projects.

Conclusion

The 20K ohm resistor is a versatile and widely used component in both analog and digital electronics. Its moderate resistance value makes it suitable for voltage dividers, pull-up/pull-down networks, signal filtering, current limiting, and transistor or op-amp biasing. Available in carbon film, metal-film, SMD, and ceramic types, it comes in various tolerances, power ratings, and temperature coefficients. Understanding its color codes, types, and applications ensures proper selection and reliable circuit performance, making the 20K ohms resistors an indispensable part of modern electronics.

Read More:

1. 1M Ohm Resistor - Color Code, Tolerance and Applications

2. 470K Ohm Resistor - Types, Color Code and Applications

3. 47 Ohm Resistor: Color Code, Specifications and Applications

HOT NEWS

The 0402 Resistor: A Comprehensive Guide

0402 Resistor

2025-05-06

Understanding A 0603 Resistor

0603 resistor,dimensions,marking code, values

2025-05-29

What is 10k Ohm Resistor?

10k resistor 10k resistor color code

2025-05-14

What Is A 1206 Resistor?

1206 resistor dimensions,footprint,value

2025-06-05

Everything You Need To Know About ARE1309 Relay

2025-04-23

MT3608 Boost Converter - An In-Depth Guide

MT3608 Boost Converter

2025-09-04

What Is The 1K Ohm Resistor?

1k ohm resistor and color code

2025-05-21

Guide To The AMS1117 Voltage Regulator

AMS1117 Voltage Regulator Circuit

2025-08-17

What is 100 Ohm Resistor And Color Code?

100 ohm resistor color code

2025-05-17

What Is The 0805 Resistor?

0805 Resistor, dimensions, value, tolerance, footprint

2025-05-31

Product Catalog

Product Catalog