220 ohm resistor is one value that frequently pops up in real-world projects—especially for hobbyists, students, and engineer. In electronics, resistors are necessary for managing current and voltage across circuits.

Whether you're building a simple LED circuit or designing an industrial interface board, this resistance value is often requisite.

This in-depth guide explores everything you need to know about the 220-ohm, from how it works to its types, color codes, power ratings, applications, and pricing.

1. What Is a 220 Ohm Resistor?

2. Key Features of a 220 Ohm Resistors

3. 220 Ohm Resistor Color Code and How to Read It

4. Resistor 220 Ohm Package Types

5. Applications of 220 Ohms Resistor

6. Wattage Ratings and Tolerance for Resistors 220 Ohm

8. Frequently Asked Questions [FAQ]

1. What Is a 220 Ohm Resistor?

A small electronic component that limits the electric current in a circuit to a safe level. The resistance fixed at 220 ohms, which means it limits how much current can pass through it. 220R is in the E24 series of preferred values use in general-purpose electronic design, offer a resistance of 220-ohms (Ω) regardless of the direction of current.

220Ω is commonly use in circuits to Protect sensitive components like LEDs (which typically operate safely at around 20 mA), prevent excess current from damaging microcontroller pins, reduce electrical noise and control voltage levels between different parts of a circuit.

The 220R is especially popular in LED circuits, because it allows just the right amount of current to flow, preventing the LED from burning out. The standard, go-to resistors value for many electronics hobbyists and professionals because its balance of current control and compatibility with 5V or 3.3V systems.

Overall, it’s useful in keeping electronic devices safe, functional, and efficient.

2. Key Features of a 220 Ohm Resistors

220Ω manufacture using various materials, each offering unique advantages:

Carbon Film: Economical and widely use in general-purpose applications.

Metal Film: Offers higher precision, stability, and lower noise.

Wirewound: Design for high-power applications, with excellent heat dissipation.

Thick Film: Common in SMD resistors, cost-effective for compact circuit boards.

Fixed Resistance Value: Provides a constant values of 220 ohms, making it ideal for applications that require predictable current or voltage control.

Widely Available: Commonly in both through-hole and surface-mount packaging types.

Versatile Usage: Suitable for a variety of functions such as current limiting, signal conditioning, voltage dividing, and circuit protection.

Multiple Tolerance Options: Available in tolerance ratings like ±1%, ±2%, ±5%, and ±10%, allowing for different levels of precision depending on the circuit requirements.

Various Power Ratings: Comes in multiple wattage options like 1/8W, 1/4W, 1/2W, 1W, 2W, 5W, and 10W, to handle different amounts of electrical power safely.

Durable Construction: Made from reliable materials such as carbon film, metal film, wirewound, or thick film, offering good thermal and mechanical stability.

Temperature and Environmental Resistance: Can operate across wide temperature ranges and coat to resist moisture, oxidation, and heat.

Easy to Identify: Clearly marked with color bands (e.g., Red-Red-Brown-Gold) or labeled directly in case of surface-mount versions (e.g., “221”).

Cost-Effective: Extremely affordable, especially when bought in bulk, making them ideal for prototyping, educational kits, and mass production.

Whether you're using them in analog signal conditioning or digital interface protection, their predictable resistance and sturdy design make them ideal.

3. 220 Ohm Resistor Color Code and How to Read It

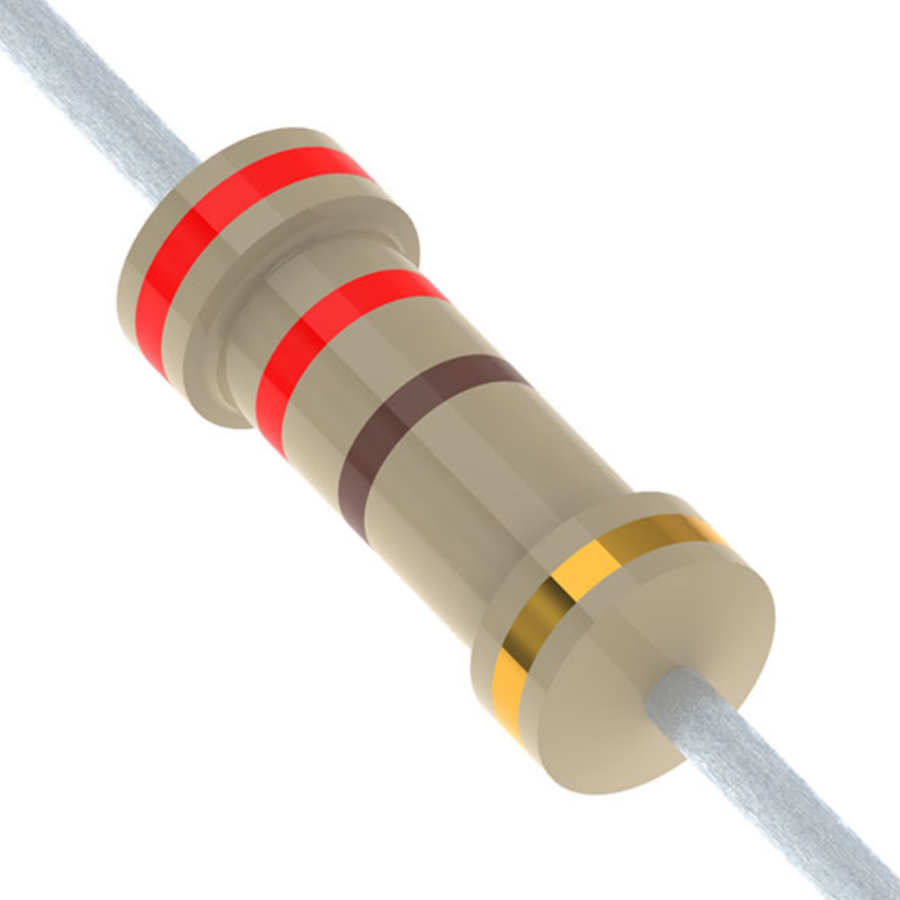

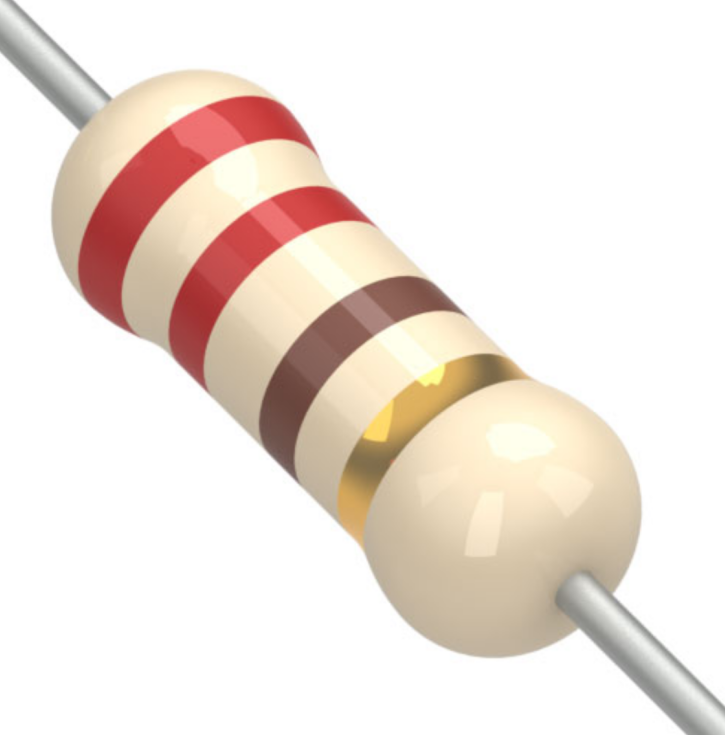

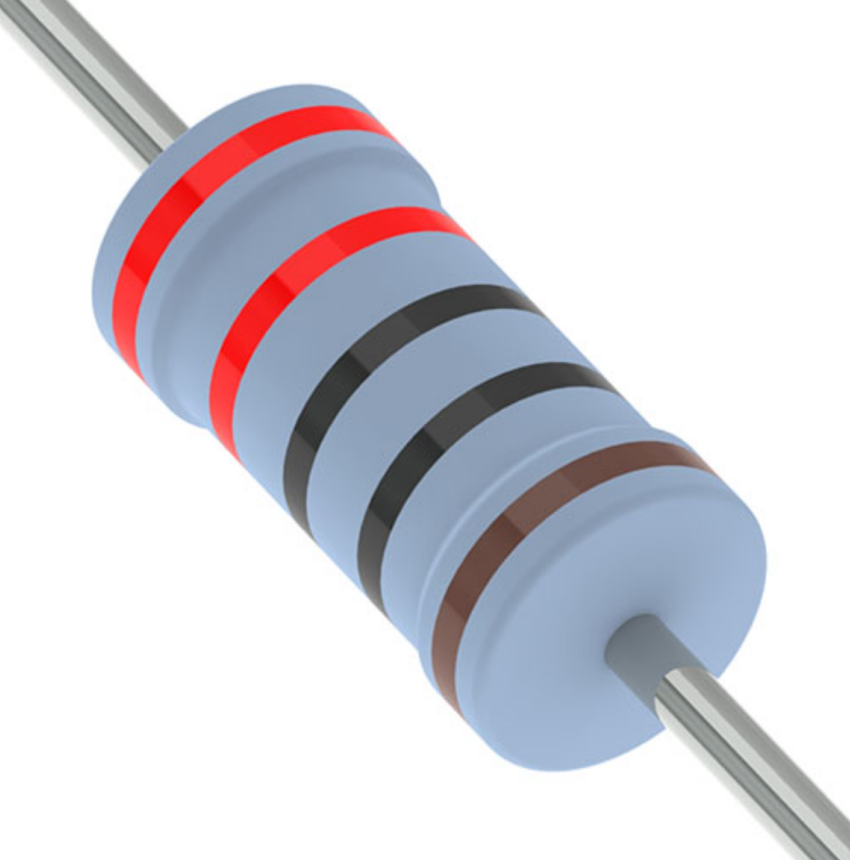

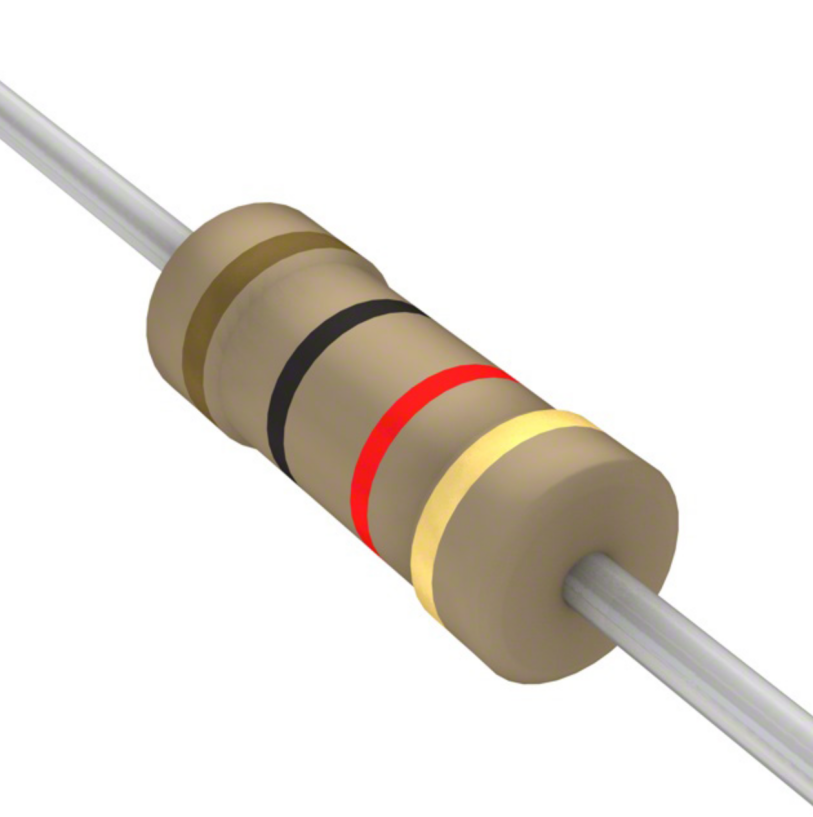

Axial resistors with colored bands that represent their resistance value and tolerance. Here's how to decode the bands for 220 ohms:

4-Band Resistor Color Code: Red - Red - Brown - Gold

Band | Color | Meaning | Value |

1st-Band | Red | 1st-Digit | 2 |

2nd-Band | Red | 2nd-Digit | 2 |

3rd-Band | Brown | Multiplier (×10) | 10 |

4th-Band | Gold | Tolerance (±5%) | ±5% |

220ohms±5% | |||

1st-Band (Red): 2, 2nd-Band (Red): 2, 3rd-Band (Brown): ×10, 4th-Band (Gold): ±5% tolerance

Calculation: Resistance = 22 × 10 = 220Ω

How to Read Step-by-Step Guide

Step 1: Understand the Band Positions

In a 4-band resistor:

The first two bands represent the first two digits of the resistance value. The third band is the multiplier (the power of ten you multiply by). The fourth band is the tolerance (how much the value may vary).

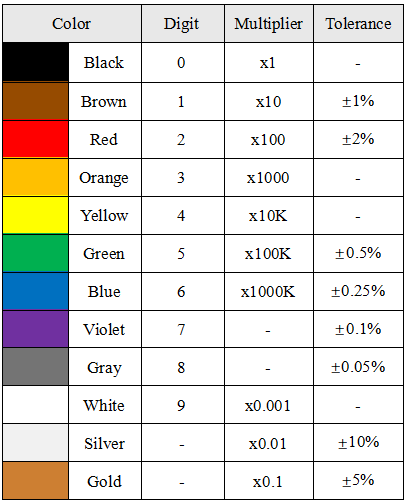

Step 2: Use the Colour Coding Table

Step 3: Decode the Bands

1st-Band (Red) = 2, 2nd-Band (Red) = 2, 3rd-Band (Brown) = Multiply by 10, 22 × 10 = 220 ohms, 4th Band (Gold) = ±5% tolerance. This means the actual resistance can vary between 209Ω and 231Ω

Quick Memory Tip:

First two bands: Write the numbers

Third band: Add the zero(s)

Fourth band: Know your tolerance range

This method works for all 4-band-resistors.

5 Band 220 Ohm Resistor : Red - Red - Black - Black - Gold

Band Position | Color | Meaning | Value |

1st-Band | Red | 1st-Digit | 2 |

2nd-Band | Red | 2nd-Digit | 2 |

3rd-Band | Black | 3rd-Digit | 0 |

4th-Band | Black | Multiplier (×1) | 1 |

5th-Band | Gold | Tolerance (±5%) | ±5% |

220ohms±5% | |||

Final Calculation:

Resistance = 220 × 1 = 220 ohms

1st-Band (Red): 2, 2nd-Band (Red): 2, 3rd-Band (Black): 0, 4th-Band (Black): Multiplier ×1, 5th-Band (Gold): ±5% tolerance

How to Read a 5-Band-Resistor:

1. Look at the first three colour bands. These represent the first three digits of the resistor’s value.

The first-band is Red, which stands for the number 2. The second-band is also Red, which is another 2. The third-band is Black, which means 0. So, the first three digits together make 220.

2. Check the fourth-band, which is the multiplier.

The fourth-band is Black, which means multiply by 1 (no change). This means the number 220 stays the same — so the resistance is 220ohms.

3. Finally, look at the fifth band, which shows the tolerance.

The fifth band is Gold, which means the resistor’s actual resistance can vary by ±5% from the stated value.

The resistor with color bands Red, Red, Black, Black, and Gold has a resistance of 220 ohms with a tolerance of plus or minus 5 percent.

Difference Between 4-Band and 5-Band Resistors

1. Number of Significant Digits

4-Band: Uses 2 significant digits, 1 multiplier band, and 1 tolerance band. So the resistance value make from the first two bands plus the multiplier.

5-Band: Uses 3 significant digits, 1 multiplier band, and 1 tolerance band. This allows for a more precise resistance value because it includes one extra digit in the value.

2. Precision

4-Band generally use where less precision is acceptable (tolerances like ±5%, ±10%).

5-Band use for more precise applications because having three digits lets you specify values more accurately (common tolerances include ±1% or better).

3. Value Range and Usage

4-Band are common in general electronics, hobby projects, and basic circuits.

5-Band favor in professional or industrial circuits where require exact resistance, such as precision amplifiers or instrumentation.

In summary:

4-band: 2 digits + multiplier + tolerance

5-band: 3 digits + multiplier + tolerance (more precise)

6-Band Colour Code: Red - Red - Black -Black - Gold - (e.g., Brown)

Band Position | Color | Meaning | Value |

1st-Band | Red | 1st-Digit | 2 |

2nd-Band | Red | 2nd-Digit | 2 |

3rd-Band | Black | 3rd-Digit | 0 |

4th-Band | Black | Multiplier | ×1 |

5th-Band | Gold | Tolerance | ±5% |

6th-Band | Brown | Temperature Coefficient (ppm/°C) | 100 ppm/°C |

220 ohms±5% 100 ppm/°C | |||

Resistance: 220 × 1 = 220 ohms

Tolerance: ±5% (possible variation in resistance)

Temperature Coefficient: 100 ppm/°C (indicates how much resistance changes with temperature)

Same as 5-band but includes a 6th-band to represent the temperature coefficient.Brown (6th Band): ±100 ppm/°C

Ideal for precision circuits sensitive to temperature variation.

Difference Between 5-Band and 6-Band Resistors

1. Number of Bands

5-Band Resistor: Has five color bands: The first three bands represent the significant digits (the resistance value). The fourth band is the multiplier. The fifth band shows the tolerance (how much the resistance can vary).

6-Band Resistor: Has six color bands, the first three bands are the significant digits. The fourth band is the multiplier. The fifth band is the tolerance. The sixth band indicates the temperature coefficient (how much the resistance changes with temperature).

2. Temperature Coefficient

The key difference is the sixth band, which is only present on 6-band resistors. This band specifies the temperature coefficient (in ppm/°C), telling you how stable the resistor’s value is when the temperature changes. Especially important for precision circuits where temperature variations could affect performance.

3. Applications

5-Band Resistors: Use when you need high precision and a specific resistance value, but temperature stability is less necessary.

6-Band Resistors: Use in high-precision, high-stability circuits like aerospace, medical, and instrumentation electronics where both accuracy and temperature stability matter.

Summary:

Feature | 5-Band | 6-Band |

Number of Color Bands | 5 | 6 |

Significant Digits | 3 | 3 |

Multiplier | Yes | Yes |

Tolerance | Yes | Yes |

Temperature Coefficient | No | Yes (6th band indicates this) |

Typical Use | High precision, general use | High precision with temperature stability |

Comparison for 4-band vs 5-band vs 6-band Color Codes:

Band Position | 4-Band | 5-Band | 6-Band |

1st-Band | Red (2) | Red (2) | Red (2) |

2nd-Band | Red (2) | Red (2) | Red (2) |

3rd-Band | Brown (Multiplier ×10) | Black (3rd-digit = 0) | Black (3rd-digit = 0) |

4th-Band | Gold (Tolerance ±5%) | Black (Multiplier ×1) | Black (Multiplier ×1) |

5th-Band | Not present | Gold (Tolerance ±5%) | Gold (Tolerance ±5%) |

6th-Band | Not present | Not present | Brown (Temperature Coefficient 100 ppm/°C) |

4. Resistor 220 Ohm Package Types

In different physical packaging, depending on how they’re mounted and the application type:

1. Through-Hole Resistor

Design to insert into holes on a PCB and solder on the other side.

Axial Resistors

Ease of Handling: Their leads make them easy to handle and place manually on breadboards or PCBs. Good Mechanical Strength: The through-hole mounting offers strong mechanical support. Widely Available: Common and inexpensive, perfect for prototyping and general electronics projects. Visible Color Code: Easy to identify resistance without special equipment.

Typical Applications: Current limiting in LEDs and small electronic circuits. Pull-up and pull-down resistors in logic circuits. Part of voltage divider circuits. Use in educational kits and DIY electronics projects. Leads on both sides of a cylindrical body. Easy to use in breadboards and prototyping

Radial Resistors

Compact Vertical Mounting: Saves PCB space by standing upright, useful in designs where board area is limited. Easy to Install: Leads can solder quickly through holes. Good for High Power: Larger radial-resistor can handle higher power than small axial types.

Typical Applications: Power supplies and voltage regulation circuits. Space-constrained boards where vertical components save room. Industrial and consumer electronics requiring medium power resistors. Circuits requiring clear resistor identification with color bands. Both leads exit from the same side. Stand vertically on the PCB. Often use in compact PCB designs.

2. Surface-mount Resistors (SMD)

Use in automated PCB manufacturing. Extremely small (common sizes: 0201, 0402, 0603, 0805, 1206, 1210, 1812, 2010, 2512). Labeled as "220R" or code like 221. SMD 220Ω are commonly in smartphones, laptops, and other compact devices.

Advantages of SMD Types: Compact Size ideal for modern electronics where space is limited. Automated Assembly, compatible with automated pick-and-place machines for mass production. High Reliability, less prone to mechanical damage compared to through-hole leads.

Applications

Use widely in mobile devices, laptops, LED circuits, power supplies, and compact embedded systems. Perfect for any application needing a reliable 220 R in a small form factor.

5. Applications of 220 Ohms Resistor

The 220 ohms is a workhorse component in both analog and digital electronics. Some of its most common applications include:

1. LED Current Limiting: To limit the current flowing through LEDs. It protects LEDs from drawing too much current, which can cause overheating and damage. Common in Arduino and Raspberry Pi circuits.

2. Microcontroller Input/Output Protection: Use to protect microcontroller pins by limiting current to and from devices like sensors, switches, or displays. Use as series resistors to prevent damage from short circuits or excessive current.

3. Voltage Divider Circuits: Often use as part of voltage divider setups to create reference voltages or scale down voltages for measurement. Helps provide precise voltage levels to other components.

4. Pull-Up and Pull-Down Resistors: Commonly use in digital circuits to ensure inputs default to a known voltage level. Prevents floating inputs that can cause erratic behavior.

5. Signal Conditioning: Helps control signal levels and filter noise in analog and digital circuits. Useful in audio equipment, sensors, and communication circuits.

6. General Current Limiting: Limits current flow to components such as transistors, LEDs, and other semiconductors, ensuring safe operation.

7. Educational and Prototyping Use: Popular in educational kits and DIY projects because its standard value and wide availability. Ideal for beginners to learn resistor’s basics and circuit design.

8. Audio Systems: Acts as impedance matching or signal attenuator

9. Filter Circuits: Combined with capacitors or inductors for low-pass, high-pass, or band-pass filters

Summary

Application Area | Description |

LED Protection | Limits current to LEDs |

Microcontroller Protection | Safeguards MCU pins |

Voltage Dividers | Creates reference voltages |

Pull-Up/Pull-Down Resistors | Stabilizes digital inputs |

Signal Conditioning | Controls and filters signal levels |

General Current Limiting | Protects various components |

Educational/Prototyping | Used in beginner and hobbyist projects |

6. Wattage Ratings and Tolerance for Resistors 220 Ohm

Determine how much power the resistor can dissipate as heat without being damaged. For a 220-ohm, different watt options are available depending on your circuit’s power requirements.

Here’s an overview of common power ratings for 220 ohms :

1. 220 Ohm 1/4 Watt Resistor

Most common rating for general electronics. Suitable for low-power circuits like LED current limiting, microcontroller inputs, and small signal applications. Compact and inexpensive.

2. 220 Ohm 1/2 Watt Resistor

Handles roughly twice the power of a 1/4 watt type. Use when expect slightly more power dissipation, such as moderate loads or higher voltage circuits. Slightly larger size to handle extra heat.

3. 220 Ohm 1 Watt Resistor

Can dissipate more heat, suitable for circuits with higher current or voltage. Often use in power supplies or circuits requiring better thermal performance.

4. 220 Ohm 2 Watt Resistor

Design for applications with significant power dissipation. Larger physical size for heat dissipation and durability. Use in industrial or high-power electronics.

5. 220 Ohm 5 Watt Resistor

Heavy-duty-resistor for high power circuits. Suitable for load testing, power regulation, and circuits where dissipate high energy.

6. 220 Ohm 10 Watt Resistor

High-power type for demanding applications. Use in power electronics, amplifiers, and industrial equipment. Requires good heat sinking to operate safely.

Summary Table:

Watt | Typical Use Case | Size / Notes |

1/4W | Low-power circuits, LED protection | Smallest, most common |

1/2W | Moderate power applications | Slightly larger |

1W | Medium power, power supplies | Larger, better heat dissipation |

2W | High power, industrial electronics | Larger, rugged |

5W | Heavy-duty, load testing | Large size, needs heat sinking |

10W | High power, industrial equipment | Largest, requires heat sinks |

Always choose a resistor with a wattage rating higher than the expected power dissipation in your circuit to ensure reliability and prevent overheating.

Wattage Rating | Maximum Current (approx) | Use Case |

1/4Watt | ~33mA | Ideal for LEDs and small circuits |

1/2Watt | ~47mA | Slightly more robust circuits |

1Watt | ~67mA | Audio circuits, motor control |

2Watt | ~95mA | Small power supplies |

5Watt | ~150mA | High-power, industrial electronics |

10Watt | ~213mA | High-current power control, heating |

These are theoretical maximums assuming full dissipation. Always allow headroom for safety.

7. 220 Ohm Resistor Price

Depends on several factors including:

Wattage rating (e.g., 1/4 watt, 1/2 watt, 1 watt, etc.), tolerance (±5%, ±1%, or tighter), type and material (carbon film, metal film, wirewound, thick film), package type (through-hole axial, SMD, power resistor), quantity purchased (bulk buying lowers the unit price) and brand.

Typical Pricing Ranges (Approximate)

Type & Wattage | Estimated Price (USD) per piece |

220-Ohm-1/4 Watt Carbon Film | $0.001~$0.005 |

220-Ohm-1/4 Watt Metal Film | $0.002~$0.01 |

220-Ohm-1/2 Watt | $0.002~$0.008 |

220-Ohm-1W | $0.005~$0.02 |

220 ohms 2 Watt and above | $0.010~$0.10 |

220R SMD (0402, 0603 sizes) | $0.0005~$0.003 |

Prices vary by order quantity. Bulk orders (1000+ pieces) typically have significantly lower per-unit cost.

Tips to Save: Buying in bulk packs or reels lowers the price drastically. Choosing standard tolerance (±5%) resistors is more economical than precision types. Bulk discounts are available.

8. Frequently Asked Questions [FAQ]

1. What color resistor is 220 ohms?

4-Band: Red – Red – Brown – Gold

5-Band: Red – Red – Black – Black – Gold

6-Band: Red – Red – Black – Black – Gold – Brown

2. What is the use of 220 ohm resistor?

A 220R is a fundamental component in electronic circuits with several uses. Limit the current flowing through components like LEDs. GPIO protection, voltage divider circuits to create reference voltages or reduce voltage levels for other parts of the circuit. Signal conditioning in controlling and stabilizing signal levels in both analog and digital circuits to improve performance and reduce noise. Protecting microcontroller Pins, pull-up and pull-down and general purpose.

3. How to tell a 220 ohm resistor?

To identify a 220Ω, check its colour bands or use a digital multimeter to measure resistance. For a 4-band , the colors are Red – Red – Brown – Gold: red (2), red (2), brown multiplier (×10), and gold tolerance (±5%). This means 22 × 10 = 220Ω. A 5-band uses Red – Red – Black – Black – Gold, representing digits 2, 2, 0, multiplier ×1, and ±5% tolerance, also 220Ω. For SMD resistors, look for the code “221”, meaning 22 × 10 = 220Ω. Using a color code chart or online calculator helps confirm the value quickly and accurately.

4. Is a 220 ohm resistor enough for LED?

Yes, commonly use and usually enough to safely limit current for most standard LEDs (20 mA current) powered by typical voltages like 5V or 3.3V. It helps prevent too much current flowing through the LED, protecting it from damage. However, the exact resistor needed depends on your LED’s forward voltage and desired brightness. For lower voltages or sensitive LEDs, you might need a higher resistance; for higher voltages or brighter LEDs, sometimes choose a lower resistance (with care). Always check the LED’s specs and use Ohm’s law or an online calculator to pick the right resistor for your setup.

5. Is 220R 220 ohms?

Yes. "220R" is the standard notation use in schematics and SMD labeling, it just a shorthand way of writing 220-ohms. The letter “R” stands for “ohms” and use to clearly indicate the decimal point or to avoid confusion with other numbers. So whenever you see 220R, it means a resistor with a resistance of 220 ohms.

6. What is the current rating of a 220 ohm resistor?

Depends mainly on its wattage (power) rating and the applied voltage. The resistor itself doesn’t have a fixed current rating but can safely carry current according to the formula:

Current (I) = √(Power rating / Resistance)

For example: A 1/4 watt (0.25W) 220Ω can handle about 33 milliamps (mA) safely. Higher wattage (like 1W or 2W) can handle proportionally more current.

Always ensure the resistor’s power rating is sufficient to handle the current in your circuit to avoid overheating or damage.

7. What is the voltage of a 220 ohm resistor?

Depends on its size and power rating.

1/4 watt usually handle up to about 200 volts.

1/2 watt can handle around 300 volts or more.

The actual voltage across the circuit depends on the current in the circuit (V = I × R). Always use a 220Ω with a voltage and power rating higher than your circuit needs to avoid damage.

Final Thoughts

The 220 ohm resistor might be small in size, but its utility is massive. From protecting LEDs to stabilizing digital signals, it's a necessary component in almost every electronics toolkit. Thanks to its widespread availability, low cost, and versatile performance, it continues to be a go-to resistor for thousands of applications.

Whether you’re a DIY electronics hobbyist, STEM student, or professional engineer, keeping a supply of 220Ω on hand is a must.

Read More:

1. 1 Ohm Resistor: A Complete Guide

HOT NEWS

The 0402 Resistor: A Comprehensive Guide

0402 Resistor

2025-05-06

Understanding A 0603 Resistor

0603 resistor,dimensions,marking code, values

2025-05-29

What Is A 1206 Resistor?

1206 resistor dimensions,footprint,value

2025-06-05

What is 10k Ohm Resistor?

10k resistor 10k resistor color code

2025-05-14

Everything You Need To Know About ARE1309 Relay

2025-04-23

MT3608 Boost Converter - An In-Depth Guide

MT3608 Boost Converter

2025-09-04

What Is The 1K Ohm Resistor?

1k ohm resistor and color code

2025-05-21

Guide To The AMS1117 Voltage Regulator

AMS1117 Voltage Regulator Circuit

2025-08-17

2512 Resistor - A Comprehensive Guide

2512 Resistor

2025-08-13

What is 100 Ohm Resistor And Color Code?

100 ohm resistor color code

2025-05-17

Product Catalog

Product Catalog